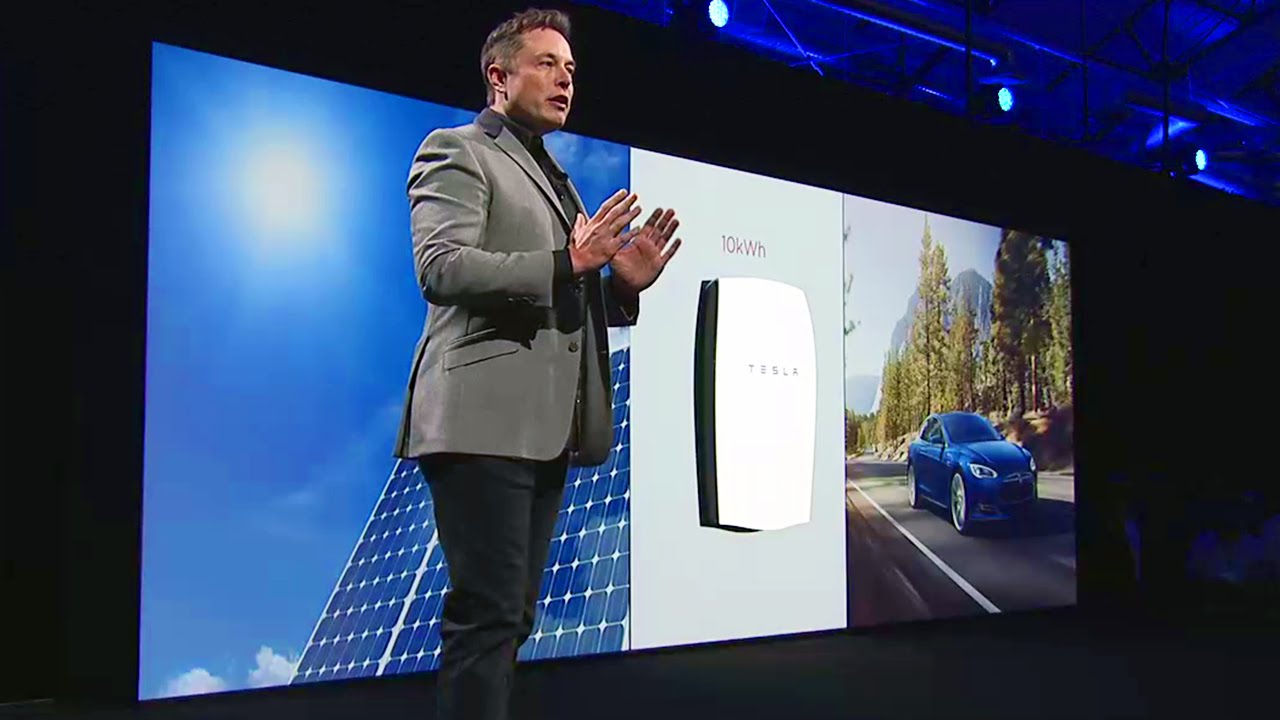

Tesla’s $3,000 Powerwall Will Let Households Run Entirely On Solar Energy

You almost certainly associate Tesla with cars – very cool cars – but the company has an even grander vision beyond that. Today, CEO and founder Elon Musk unveiled ‘Tesla Energy’ – a new business arm that is focused on ending our dependence on grid power and switching instead to solar energy.

The first Tesla Energy product is ‘Powerwall Home Battery,’ a stationary battery that can power a household without requiring the grid. The battery is rechargeable lithium-ion – it uses Tesla’s existing battery tech – and can be fixed to a wall, removing much of the existing complexity around using a local power source.

“The issue with existing batteries is that they suck,” Musk said in a press conference announcing Tesla Energy. “They are expensive, unreliable and bad in every way.”

Tesla’s solution, he said, is different.

For one thing, the company’s batteries cost $3,500 for 10kWh and $3,000 for 7kWh – add your snarky Apple Watch price comparison here. They are open for pre-orders in the U.S. now, the first orders will be dispatched “in late summer.”

Like regular batteries, they can be used together – up to nine can stacked up together to create a strong and reliable power source. Musk said he believes they can help people in emerging markets or remote locations ‘leapfrog’ the need for existing power systems, in a similar way that mobile phones have become more important than landlines in remote parts of the world.

A Tesla car is (sadly) not included with your puchase

The Tesla Powerwall charges up using solar power, but it also integrates with the grid “to harness excess power and give customers the flexibility to draw energy from their own reserve”. The batteries recharge in a ‘smart’ way, saving money by picking low rate periods when electricity is cheapest. They store solar energy for later, for example overnight, and can act as a back-up in the event of a power outage.

Removing dirty energy is an ambitious plan – much like space travel – but Musk believes it can be done. He explained that 160 million battery packs could “transition” power usage in the U.S. to renewable energy, while 900 million units could shift the entire world’s energy needs. Then there is the potential to make the world’s cars run on clean energy.

“This is within the power of humanity to do,” Musk said. “It is not impossible, it is something that we can do. But there’s going to [need to] be other companies involved.”

Musk added that Tesla will continue its policy of open-sourcing patents to help make that happen.

Contrary to most companies these days, Tesla’s press conference – which ran entirely on solar energy – was direct and to the point with little hyperbole.

Musk has made electric cars a (stylish) reality, and is pioneering space exploration with SpaceX. Tesla Energy is another concept which, though beyond the realm of most people’s understanding, has potentially huge consequences if Tesla can execute as Musk believes it can.

If you Love a Tiny House, Then You’ll Really Love A Tiny Houseboat!

Have you ever wanted to just up and quit your job, build a boat, and travel the world? Sure, that might seem a little extreme, but maybe one day at least part of the package can come true.

Enter Roy Schreyer of Roy Designed That who designs and builds awesome things. His projects require a great deal of skill, but Roy shares his creations with the world, the hope being that others will give his designs and projects a try too.

That’s why when I came across his DIY tiny houseboat, I was super excited. I’ve always loved boats – there’s something very relaxing about being out on the water. Hours fly by and seem to stand still at the same time. But how cool would it be to have a little boat that you could cruise around in all day, and then instead of having to leave the boat behind at the dock, you can anchor it and spend the night right there. That sounds pretty cool to me.

Roy Schreyer has many designs, but this one is by far my favorite.

It’s a tiny houseboat. The structure was built with minimalist principles to make the best use out of space.

One of the benefits of the boat’s size is that you can anchor it almost anywhere! Take off for a weekend or just cruise around the lake for an afternoon.

It’s actually a lot roomier on the inside than you’d think. With this set up, there’s enough space for several people to sit comfortably.

The seating area can also be converted into a bedroom. I can just imagine falling asleep to the sound of the waves against the boat.  RoyDesignedThat

RoyDesignedThat

The steering column is an old-fashioned wooden wheel with spokes that hearken back to the days of tall ships.

The inside is surrounded by windows so everyone is guaranteed a good view.

It wouldn’t be a Tiny Houseboat without a space for the most important time of the day – mealtime! In addition to a seating area and a bedroom, the cabin can also be converted into a dining room.

You can dock this little guy anywhere, including a sandbar for an afternoon picnic.

Here’s a video of the Tiny Houseboat in action:

Original source: viralnova

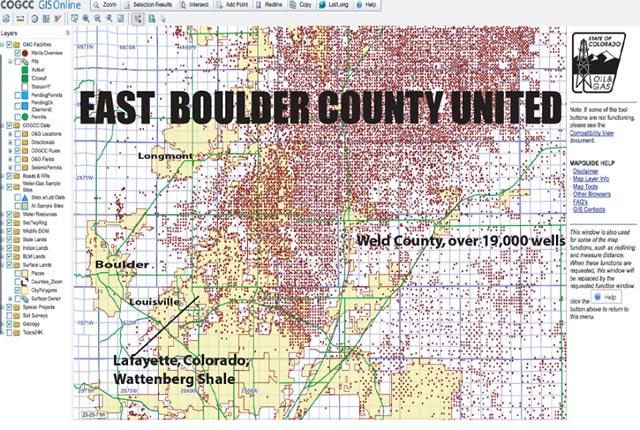

Colorado Communities Battle Energy Industry to Build Community Rights

On the Wattenberg shale of Colorado, it was recently reported that the Larimer Energy Action Project, an extension of the Colorado oil and gas industry, contributed $20,000 to the Fort Collins City Council campaign of Ray Martinez. With this contribution and the electoral victory of Martinez, the industry successfully extended its influence over a community defending a democratically mandated five-year moratorium on oil and gas drilling.

The industry knows that its control of the state legislature, legal system and courts is not sufficient. Community members standing up to the inherently dangerous oil and gas industry aren’t entering the effort from high political office. The movement against fracking comes from below, from the real grassroots, making local councils the logical next battleground between corporate power and community and environmental rights.

It is natural that the city councils now become contested. Prior to the recent elections in Fort Collins, as recently as February 2015, the Windsor, Colorado, city clerk refused to allow local citizens a vote on a Windsor Community Bill of Rights that would ban oil and gas drilling. All during local campaigns against fracking in 2013, city councils weighed in to push community efforts into the more controllable arenas of lobbying and letter writing. The Lafayette City Council went so far as to endorse a resolution broadly condemning the Lafayette Community Bill of Rights to ban fracking. Two weeks later, the Lafayette Community Bill of Rights passed with more than 60 percent of the popular vote, and two local candidates who endorsed the resolution were elected to the City Council.

The oil and gas industry does not rest in its harassment of local governments. At the moment a community begins to approach drilling from even a cautionary position, town meetings find the seats packed with oil and gas employees, and community members are called in their homes by industry PR firms. Communications from law firms hired by the Colorado Oil and Gas Association are sent to city councils threatening expensive litigation and taking claims aimed squarely at the local treasuries.

Although the general trend of local councils has been to submit to state law that protects corporations – and request that their constituents do the same – two Colorado cities, Longmont and Fort Collins, did appeal lower court decisions. In the event the courts rule against the people of these municipalities, the offending laws will be considered unenforceable. The Colorado Oil and Gas Association will then have determined local law.

A New Type of Local Official

Some years ago many local people started to believe that political careers could be made and broken upon the dual issues of fracking and community rights. Where communities are not led by city councilors willing to do what is necessary to battle the inherently dangerous process of fracking and the legal system that forces it onto their constituents, local officials will be forced to choose which demands to suppress: those of the state and industry, or those of their own community members.

At this point, a new type of local official is beginning to emerge. Lafayette City Councilor Merrily Mazza, who ran as an independent candidate from the grassroots effort that banned fracking in the same election, built her campaign for office as a means to drive the debate around fracking and mobilize the community.

Now elected to office, she continues to build the local grassroots effort from the City Council. The difference between Mazza and conventional politicians is that she does not see resolution coming from one new official or another. She identifies the real vehicle of change as the community itself. When Boulder District Judge D.D. Mallard declared that Lafayette constituents could not write laws barring oil and gas activity from harming them, her answer was simple: “If the courts do not recognize our citizen’s authority to create laws to protect our fundamental rights, then the courts no longer are ruling from a position of democratic or moral authority. The Lafayette City Council should therefore resolve to reject the judge’s decision, and fully enforce the Lafayette Community Bill of Rights.” The Lafayette City Council has been less than welcoming to that idea.

No other Colorado politician has been willing to side with his or her citizens in this way. If the pattern plays out, Mazza will be the first of many such candidates unwilling to yield to the courts and industry at the cost of her community. And then standard campaigns and lobbying will transition into genuine historic movements.

We need more movement officials, and their qualifications are basic and important. They are pushed forward by the efforts of local community members; they see their campaigns and offices only as a means to build those local struggles; they are able to articulate the systemic nature of problems like fracking and they are willing to disobey any order that places the rights and health of their constituents below the demands of corporations and the politicians and judges that serve to advance those corporate interests.

After all, if we are not able to enact laws to protect our rights, and those laws that we do create to protect ourselves from the harms associated with projects like fracking are said to be unenforceable, by what authority are the courts and government ruling? Under what obligation are we to governmental authority that abuses the very people and communities it claims to represent?

Defying the Courts, Defending the Community

At this point, doors begin to open. For example, if a city council had a majority of members who campaigned and governed along these principles, could the local police department be ordered to enforce the laws of the community rather than the rulings of the courts and the corporations they are siding with? Could community members be empowered to enforce democratically mandated laws like the Lafayette Community Rights Amendment to Ban Fracking? Given that the officers of local communities are obligated to enforce the municipal law or charter, could the city council take a resolution that anyone acting to enforce laws designed to protect the fundamental rights of community members against industries attempting to violate the laws will not be interfered with by local law enforcement?

This is not only possible; it begins to act on the very democratic principles that we were taught from a very young age. The US Declaration of Independence itself asserts that, “Governments are instituted among Men, deriving their just powers from the consent of the governed, That whenever any Form of Government becomes destructive of these ends, it is the Right of the People to alter or to abolish it, and to institute new Government, laying its foundation on such principles and organizing its powers in such form, as to them shall seem most likely to effect their Safety and Happiness.” Colorado communities are apparently taking the document at its worth.

We have found ourselves in a time where the benefits of the law are conveyed to the few, at the cost of the many. Communities across Colorado have pushed forward to remedy this problem, and are not content to wait for the half measures and delays pouring out of our courts and government like oil from a wellhead explosion. The local officials we currently have will continue to be asked, “Which side are you on?” To the extent the answer is not “the people’s,” the movement for community rights and against fracking and corporate power will find individuals willing to build the movement to new heights.

The laws and politicians endangering our communities will change, and the ones replacing them will begin to establish the ground for a much broader struggle – one that no longer peers though the windows into the halls of power, but one that starts to take power of its own.

Solar power will soon be as cheap as coal

This post originally appeared at Ensia.

Inside a sprawling single-story office building in Bedford, Massachusetts, in a secret room known as the Growth Hall, the future of solar power is cooking at more than 2,500 °F. Behind closed doors and downturned blinds, custom-built ovens with ambitious names like “Fearless” and “Intrepid” are helping to perfect a new technique of making silicon wafers, the workhorse of today’s solar panels. If all goes well, the new method could cut the cost of solar power by more than 20% in the next few years.

“This humble wafer will allow solar to be as cheap as coal and will drastically change the way we consume energy,” says Frank van Mierlo, CEO of 1366 Technologies, the company behind the new method of wafer fabrication.

Secret rooms or not, these are exciting times in the world of renewable energy. Thanks to technological advances and a ramp-up in production over the decade, grid parity-the point at which sources of renewable energy such as solar and wind cost the same as electricity derived from burning fossil fuels-is quickly approaching. In some cases it has already been achieved, and additional innovations waiting in the wings hold huge promise for driving costs even lower, ushering in an entirely new era for renewables.

Solar surprise

In Jan. 2015, Saudi Arabian company ACWA Power surprised industry analysts when it won a bid to build a 200-megawatt solar power plant in Dubai that will be able to produce electricity for 6 cents per kilowatt-hour. The price was less than the cost of electricity from natural gas or coal power plants, a first for a solar installation. Electricity from new natural gas and coal plants would cost an estimated 6.4 cents and 9.6 cents per kilowatt-hour, respectively, according to the US Energy Information Agency.

Technological advances, including photovoltaics that can convert higher percentages of sunlight into energy, have made solar panels more efficient. At the same time economies of scale have driven down their costs.

For much of the early 2000s, the price of a solar panel or module hovered around $4 per watt. At the time Martin Green, one of the world’s leading photovoltaic researchers, calculated the cost of every component, including the polycrystalline silicon ingots used in making silicon wafers, the protective glass on the outside of the module, and the silver used in the module’s wiring. Green famously declared that so long as we rely on crystalline silicon for solar power, the price would likely never drop below $1/watt.

The future, Green and nearly everyone else in the field believed, was with thin films, solar modules that relied on materials other than silicon that required a fraction of the raw materials.

Then, from 2007 to 2014, the price of crystalline silicon modules dropped from $4 per watt to $0.50 per watt, all but ending the development of thin films.

The dramatic reduction in cost came from a wide number of incremental gains, says Mark Barineau, a solar analyst with Lux Research. Factors include a new, low-cost process for making polycrystalline silicon; thinner silicon wafers; thinner wires on the front of the module that block less sunlight and use less silver; less-expensive plastics instead of glass; and greater automation in manufacturing.

“There is a tenth of a percent of an efficiency gain here and cost reductions there that have added up to make solar very competitive,” Barineau says.

25 cents per watt

“Getting below $1 [per watt] has exceeded my expectations,” Green says. “But now, I think it can get even lower.”

One likely candidate to get it there is 1366’s new method of wafer fabrication. The silicon wafers behind today’s solar panels are cut from large ingots of polycrystalline silicon. The process is extremely inefficient, turning as much as half of the initial ingot into sawdust. 1366 takes a different approach, melting the silicon in specially built ovens and recasting it into thin wafers for less than half the cost per wafer or a 20% drop in the overall cost of a crystalline silicon module. 1366 hopes to begin mass production in 2016, according to van Mierlo.

Meanwhile, thin films, once thought to be the future of solar power, then crushed by low-cost crystalline silicon, could experience a renaissance. The recent record-setting low-cost bid for solar power in Dubai harnesses thin-film cadmium telluride solar modules made by US manufacturer First Solar. The company not only hung on as the vast majority of thin film companies folded, but has consistently produced some of the least expensive modules by increasing the efficiency of their solar cells while scaling up production. The company now says it can manufacture solar modules for less than 40 cents per watt and anticipates further price reductions in coming years.

Ten years from now we could easily see the cost of solar modules dropping to 25 cents per watt, or roughly half their current cost, Green says. To reduce costs beyond that, the conversion efficiency of sunlight into electricity will have to increase substantially. To get there, other semiconducting materials will have to be stacked on top of existing solar cells to convert a wider spectrum of sunlight into electricity.

“If you can stack something on top of a silicon wafer it will be pretty much unbeatable,” Green says.

Green and colleagues set a record for crystalline silicon solar module efficiency at 22.9% in 1996 that still holds today. Green doubts the efficiency of crystalline silicon alone will ever get much higher. With cell stacking, however, he says “the sky is the limit.”

A matter of size

While solar power is just starting to reach grid parity, wind energy is already there. In 2014, the average worldwide price of onshore wind energy was the same as electricity from natural gas, according to Bloomberg New Energy Finance.

As with solar, the credit goes to technological advances and volume increases. For wind, however, innovation has mainly been a matter of size. From 1981 to 2015 the average length of a wind turbine rotor blade has increased more than sixfold, from 9 meters to 60 meters, as the cost of wind energy has dropped by a factor of 10.

“Increasing the rotor size means you are capturing more energy, and that is the single most import driver in reducing the cost of wind energy,” says D. Todd Griffith of Sandia National Laboratories in Albuquerque, New Mexico.

Griffith recently oversaw the design and testing of several 100-meter-long blade models at Sandia. His group didn’t actually build the blades, but created detailed designs that they subsequently tested in computer models. When the project started in 2009, the biggest blades in commercial operation were 60 meters long. Griffith and his colleagues wanted to see how far they could push the trend of ever-increasing blades before they ran into material limitations.

Their first design was an all-fiberglass blade that used a similar shape and materials as those found in relatively smaller commercial blades at the time. The result was a prohibitively heavy 126-ton blade that was so thin and long it would be susceptible to vibration in strong winds and gravitational strain.

The group made two subsequent designs employing stronger, lighter carbon fiber and a blade shape that was flat-backed instead of sharp-edged. The resulting 100-meter blade design was 60% lighter than the initial model.

Since the project began in 2009 the largest blades used in commercial offshore wind turbines have grown from 60 meters to roughly 80 meters with larger commercial prototypes now under development. “I fully expect to see 100 meter blades and beyond,” Griffith says.

As blades grow longer, the towers that elevate them are getting taller to catch more consistent, higher speed wind. And as towers grow taller, transportation costs are growing increasingly expensive. To counter the increased costs GE recently debuted a “space frame” tower, a steel lattice tower wrapped in fabric. The new towers use roughly 30% less steel than conventional tube towers of the same height and can be delivered entirely in standard-size shipping containers for on-site assembly. The company recently received a $3.7 million grant from the US Department of Energy to develop similar space frame blades.

Offshore innovation

Like crystalline silicon solar panels, however, existing wind technology will eventually run up against material limits. Another innovation on the horizon for wind is related instead to location. Wind farms are moving offshore in pursuit of greater wind resources and less land use conflict. The farther offshore they go, the deeper the water, making the current method of fixing turbines to the seafloor prohibitively expensive. If the industry moves instead to floating support structures, today’s top-heavy wind turbine design will likely prove too unwieldy.

One potential solution is a vertical axis turbine, one where the main rotor shaft is set vertically, like a merry go round, rather than horizontally like a conventional wind turbine. The generator for such a turbine could be placed at sea level, giving the device a much lower center of gravity.

“There is a very good chance that some other type of turbine technology, very well vertical axis, will be the most cost effective in deep water,” Griffith says.

The past decade has yielded remarkable innovations in solar and wind technology, bringing improvements in efficiency and cost that in some cases have exceeded the most optimistic expectations. What the coming decade will bring remains unclear, but if history is any guide, the future of renewables looks extremely positive.

The Quest for Electromagnetic ‘Full Absorption’ and the End of Power Lines

”Harvesting the energy of electromagnetic waves” sounds redundant. As energy is a thing at all

In the new paper, researchers at the University of Waterloo describe the use of metasurfaces etched with different patterns of shapes, with each variation acting as a resonator that can be tuned to target a particular frequency. This tunability allows the material to achieve “full unity” (or very close to it) in its absorption of electromagnetic waves. This absorbed energy is then shuttled away from the surface through a conducting path connected to a resistant load (sort of an electrical sponge).

Image: AIP/Waterloo

The idea is that a material like this could employed in such a way to match the ambient electromagnetic radiation of a given environment, or free-space impedance.

One potential application is in space-based solar energy harvesting. Via conventional solar panels, some satellite power plant would capture energy, which would then be converted into microwaves. These microwaves could then be beamed down at surface microwave collector farms. This could be a lot more bang per solar buck.

Solar Power Battle Puts Hawaii at Forefront of Worldwide Changes

HONOLULU – Allan Akamine has looked all around the winding, palm tree-lined cul-de-sacs of his suburban neighborhood in Mililani here on Oahu and, with an equal mix of frustration and bemusement, seen roof after roof bearing solar panels.

Mr. Akamine, 61, a manager for a cable company, has wanted nothing more than to lower his $600 to $700 monthly electric bill with a solar system of his own. But for 18 months or so, the state’s biggest utility barred him and thousands of other customers from getting one, citing concerns that power generated by rooftop systems was overwhelming its ability to handle it.

Only under strict orders from state energy officials did the utility, the Hawaiian Electric Company, recently rush to approve the lengthy backlog of solar applications, including Mr. Akamine’s.

It is the latest chapter in a closely watched battle that has put this state at the forefront of a global upheaval in the power business. Rooftop systems now sit atop roughly 12 percent of Hawaii’s homes, according to the federal Energy Information Administration, by far the highest proportion in the nation.

“Hawaii is a postcard from the future,” said Adam Browning, executive director of Vote Solar, a policy and advocacy group based in California.

Other states and countries, including California, Arizona, Japan and Germany, are struggling to adapt to the growing popularity of making electricity at home, which puts new pressures on old infrastructure like circuits and power lines and cuts into electric company revenue.

As a result, many utilities are trying desperately to stem the rise of solar, either by reducing incentives, adding steep fees or effectively pushing home solar companies out of the market. In response, those solar companies are fighting back through regulators, lawmakers and the courts.

The shift in the electric business is no less profound than those that upended the telecommunications and cable industries in recent decades. It is already remaking the relationship between power companies and the public while raising questions about how to pay for maintaining and operating the nation’s grid.

The issue is not merely academic, electrical engineers say.

In solar-rich areas of California and Arizona, as well as in Hawaii, all that solar-generated electricity flowing out of houses and into a power grid designed to carry it in the other direction has caused unanticipated voltage fluctuations that can overload circuits, burn lines and lead to brownouts or blackouts.

“Hawaii’s case is not isolated,” said Massoud Amin, a professor of electrical and computer engineering at the University of Minnesota and chairman of the smart grid program at the Institute of Electrical and Electronics Engineers, a technical association. “When we push year-on-year 30 to 40 percent growth in this market, with the number of installations doubling, quickly – every two years or so – there’s going to be problems.”

The economic threat also has electric companies on edge. Over all, demand for electricity is softening while home solar is rapidly spreading across the country. There are now about 600,000 installed systems, and the number is expected to reach 3.3 million by 2020, according to the Solar Energy Industries Association.

The Edison Electric Institute, the main utility trade group, has been warning its members of the economic perils of high levels of rooftop solar since at least 2012, and the companies are responding. In February, the Salt River Project, a large utility in Arizona, approved charges that could add about $50 to a typical monthly bill for new solar customers, while last year in Wisconsin, where rooftop solar is still relatively rare, regulators approved fees that would add $182 a year for the average solar customer.

In Hawaii, the current battle began in 2013, when Hawaiian Electric started barring installations of residential solar systems in certain areas. It was an abrupt move – a panicked one, critics say – made after the utility became alarmed by the technical and financial challenges of all those homes suddenly making their own electricity.

The utility wants to cut roughly in half the amount it pays customers for solar electricity they send back to the grid. But after a study showed that with some upgrades the system could handle much more solar than the company had assumed, the state’s public utilities commission ordered the utility to begin installations or prove why it could not.

It was but one sign of the agency’s growing impatience with what it considers the utility’s failure to adapt its business model to the changing market.

Hawaiian Electric is scrambling to accede to that demand, approving thousands of applications in recent weeks. But it is under pressure on other fronts as well. NextEra Energy, based in Florida, is awaiting approval to buy it, while other islands it serves are exploring defecting to form their own cooperative power companies.

It is also upgrading its circuits and meters to better regulate the flow of electricity. Rooftop solar makes far more power than any other single source, said Colton Ching, vice president for energy delivery at Hawaiian Electric, but the utility can neither control nor predict the output.

“At every different moment, we have to make sure that the amount of power we generate is equal to the amount of energy being used, and if we don’t keep that balance things go unstable,” he said, pointing to the illuminated graphs and diagrams tracking energy production from wind and solar farms, as well as coal-fueled generators in the utility’s main control room. But the rooftop systems are “essentially invisible to us,” he said, “because they sit behind a customer’s meter and we don’t have a means to directly measure them.”

For customers, such explanations offer little comfort as they continue to pay among the highest electric rates in the country and still face an uncertain solar future.

“I went through all this trouble to get my electric bill down, and I am still waiting,” said Joyce Villegas, 88, who signed her contract for a system in August 2013 but was only recently approved and is waiting for the installation to be completed.

Mr. Akamine expressed resignation over the roughly $12,000 he could have saved, but wondered about the delay. “Why did it take forceful urging from the local public utility commission to open up more permits?” he asked.

Installers – who saw their fast-growing businesses slow to a trickle – are also frustrated with the pace. For those who can afford it, said James Whitcomb, chief executive of Haleakala Solar, which he started in 1977, the answer may lie in a more radical solution: Avoid the utility and its grid altogether.

Customers are increasingly asking about the batteries that he often puts in along with the solar panels, allowing them to store the power they generate during the day for use at night. It is more expensive, but it breaks consumer reliance on the utility’s network of power lines.

“I’ve actually taken people right off the grid,” he said, including a couple who got tired of waiting for Hawaiian Electric to approve their solar system and expressed no interest in returning to utility service. “The lumbering big utilities that are so used to taking three months to study this and then six months to do that – what they don’t understand is that things are moving at the speed of business. Like with digital photography – this is inevitable.”

3 Suppressed Technologies that Could Revolutionize Daily Life

By Nick Bernabe

The US has a long history of suppressing technologies in an effort to help government aligned corporations extend their profits. This history dates back over 100 years which we will outline – in part – in this article.

Nikola Tesla, the man who discovered how to use Alternating Current (AC) electricity, has many rumors surrounding his life. Born in 1856, he has basically disappeared from the history books, only for people to rediscover his work thanks to the internet.

He was a well known inventor in his time, first arriving in America to work for Thomas Edison. He later branched out on his own in disgust of Thomas Edison’s business practices. A rivalry between Tesla and Edison soon became apparent as the debate over AC/DC electricity heated up. Tesla, who ended up winning the debate, argued that AC electricity was more efficient and cost effective, which was true.

Tesla was also involved in many more controversial projects. Much of his work was undermined by Edison himself, who attempted to destroy Tesla’s reputation. There was also a concerted effort by bankers to bankrupt Tesla in order to stop his research that could have threatened their own businesses.

One such project was the transmission of basically free wireless electricity, an idea that is literally revolutionizing. Wireless energy would put many power companies and oil companies out of business. Tesla was working on this project late into his life, after he had fallen into bankruptcy and was living in a hotel room. It was long suspected that the FBI literally stole all of his work, research, and inventions that he had in his possession when he died. This rumor has now been confirmed by recent, heavily redacted Freedom of Information Act requests released by the FBI which you can read by clicking on the image below.

Here is a video demonstrating Tesla’s suppressed inventions, whether due to FBI intervention, or corporate espionage waged by Edison and banker J.P. Morgan:

WHO KILLED THE ELECTRIC CAR AND WHY?

There was a concerted effort by oil companies, car manufacturers, and the government to stop the rise of the electric car in the 90′s.

You can watch the full documentary titled “Who Killed the Electric Car” here.

HEMP/CANNABIS

Documented previously in our article titled “34 Medical Studies Proving Cannabis Cures Cancer“, we show that there are plenty of potential uses for cannabis that can cure cancer and help treat other ailments. This is an understandable threat to the current medical-industrial-complex that banks billions on cancer treatments every year.

The many industrial uses for hemp made the plant highly dangerous to current corporate establishments such as paper, plastic, and oil industries. There are reportedly 50,000 different industrial uses for hemp.

This threat to industry has led to an aggressive government funded, corporate backed anti-cannabis propaganda campaign that has spanned decades.

Credit: The Mind Unleashed

ABOUT THE AUTHOR:

Nick Bernabe is the owner and lead editor of the website TheAntiMedia.org, an activist, blogger, and the founder and spokesman of the March Against Monsanto movement. He is also a guest contributor to The Mind Unleashed. Please follow his Facebook page by clicking here.

Sometimes Newer Isn’t Always Better

Some tools are just timeless classics. We often assume that a more modern version of a tool is superior to some of the older, but tried and true, models. This isn’t always the case, as you can see here.

The scythe is:

- Inexpensive

- Quiet

- Faster at clearing tall weeds

- Badass

VS

The weedwacker, which is:

- Incredibly noisy, contributing to noise pollution

- Gas powered, which contributes to air pollution

- Slower

- More expensive

- Harder to repair

Let’s not assume newer is better. Give the classics another try.

VW Bus to be re-released as an electric vehicle

The Volkswagen Westfalia Camper ceased production in 2003, but board member Dr Heinz-Jakob Neusser revealed that the bus will be coming back as an electric vehicle.

Though images of the new vehicle have yet to be released, Neusser explained that the Camper will have a small electric motor to power the front wheels; the batter packs will be under the floor. He added that it will feature three key design cues, reminicent of the VW Bus, “first the wide, solid, D-Pillar, second the boxy design of the center section and, thirdly, the front end must have a very short overhang. The distance from the A-pillar to the front end must be very short.”

The original vehicle looking something like this

There is no certainty this will hit the market, according to Neusser, but with an attractive enough cost-base it most definitely will.

And demand. Would you drive one? If they had solar panels in the 60’s…

Volkswagen has also released two othe campers in recent years, the Microbus

and the Bulli

Volkswagen has also announced it will be investing $10 million in electric charging infrastructure by 2016.

Here are some images of Volkswagen’s Bulli, inside and out, with some swanky jazz music

Image Credit: http://www.autocar.co.uk/car-news/motor-shows-new-york-motor-show/volkswagen-camper-return-electric-vehicle

Image Credit: http://www.autocar.co.uk/car-news/motor-shows-new-york-motor-show/volkswagen-camper-return-electric-vehicle  http://inhabitat.com/classic-vw-camper-van-to-be-revived-as-a-battery-electric-vehicle/

http://inhabitat.com/classic-vw-camper-van-to-be-revived-as-a-battery-electric-vehicle/

This blog is free & open source, however embeds may not be.

This solar-powered e-bike has a top speed of 30 mph

The Solar Bike features cells built into both sides of both wheels that are, according to Frausig, highly efficient and “shadow optimized.” When the bike is parked it can garner enough power from available sunlight for a range of 2-25km (1.2-15.5 miles) each day (depending on cloud cover, and, one might assume, on the angle at which the bike is parked), and can store enough electricity in its thermos-shaped battery for a 70km (40 mile) range.

Related: Cyclist journeys from France to Japan on a solar electric bike

As you cycle, the solar cells trickle through whatever electricity they generate to help power the bike in addition to stored power. That electric assist carries some fairly serious wallop; the bike has a standard speed of 15mph, and a top speed of 30-which is almost certainly more than you need to make it through the commute to work. Additionally, the on-board lights are solar-powered.

The bike is the product of three years of work by Jesper Frausig, and the current version is his second prototype. While there’s no word yet on if or when the bike will go into production, or how much it might cost, it has been nominated for an INDEX: Design to improve life Award.

Via Engadget

New cheap, flexible aluminum battery charges in a minute flat

Researchers at Stanford University’s Precourt Institute for Energy have unveiled a new aluminum-ion battery that could one day replace the lithium-ion (Li-ion) batteries we use to power pretty much everything, from our watches to our tablets and our electric vehicles. The aluminum battery can be produced more cheaply than current alternatives, is not quite so bad for the environment as alkaline batteries, and unlike Li-ion batteries, it won’t explode -“even if you drill through it.”

The concept of creating an aluminum battery is nothing new; researchers have been toying with the idea for decades. It’s an attractive concept due to its safety, low cost, and high durability-and what Stanford has developed may be the closest thing we’ve seen to a commercially viable product. It utilizes a negatively charged anode, made from aluminum, and a positively charged cathode made from graphite along with an ionic liquid electrolyte, all of which is contained within a flexible polymer-coated pouch. Bending cell phones anyone?

Related: Phinergy’s recyclable aluminum-air battery could power EVs for thousands of miles

The prototype can charge in just one minute-which stands in pretty staggering contrast to the time many of us spend sitting around waiting for our cellphone to charge-and can be recharged at least 7,500 times. The Stanford team says they have unpublished data to show it can hold up for even more charge cycles than that. And that holds a fascinating potential for efficient grid scale storage of renewable energy, where batteries need to be able to rapidly store and release energy many times over.

For now, the much smaller scale prototype produces around two volts, notably less than the 3.6 that is standard for li-ion batteries. Additionally, Engadget notes, the aluminum battery doesn’t quite perform as well as lithium batteries in terms of power density: “aluminum cells only carry 40 watts of electricity per kilogram compared to lithium’s 100 to 206 W/kg power density.”

As Stanford professor Hongjie Dai noted in a press release, “Otherwise, our battery has everything else you’d dream that a battery should have: inexpensive electrodes, good safety, high-speed charging, flexibility and long cycle life. I see this as a new battery in its early days. It’s quite exciting.”

Via Engadget

Images via Shutterstock and Stanford Precourt Institute for Energy via YouTube screengrab.

Are Dutch Docklands’ Floating Islands a Sustainable Alternative to Dubai’s Sinking World Islands?

This is not the first time that floating islands have been proposed as a solution to the struggling “World” islands project, in which hundreds of little islands collectively shaped like the world are being developed in the Arabian/Persian Gulf (depending on who you talk to). Earlier a Dubai-based firm submitted the Ome project.

Dutch Docklands also worked on The Floating Proverb – a curious collection of 89 floating islands that spell out an Arab proverb when viewed from above – for the Nakheel development company. Dutch Docklands CEO Paul van de Camp told the paper that the concept is still alive. When (not if) it takes off, the self-supportable floating islands will be constructed with existing landmasses, saving investors a considerable amount of money and trouble. For examples of what these floating islands might look like, check out these pics of Dutch Docklands’ Floating Golf Course in the Maldives!

Via Emirates 24/7

Stanford researchers harvest electricity from algae, unkempt pools become gold mines

Green energy, from underwater turbines to the Bloom Box, we’re always up for another. Running along the same lines as Uppsala University’s algae-based batteries, researchers at Stanford are generating electrical current by tapping into the electron activity of individual algae cells. The team designed a gold electrode that can be pushed through a cell membrane, which then seals around it. The cell, still alive, does what it does best (photosynthesis), at which point scientists harvest chemical energy in the form of electrons. According to Stanford University News, this results in “electricity production that doesn’t release carbon into the atmosphere. The only byproducts of photosynthesis are protons and oxygen.” Of course, the team has a long way to go before this is economically feasible, but who knows? Maybe there’s an algae-powered OPhone in your future…

Artificial Leaf Can Make Oxygen in Space with Water and Light

It seems like we are constantly getting a little bit closer to being able to live in outer space, but one teeny-tiny little detail keeps holding us back: oxygen. Plants just don’t like zero gravity environments, and toting around an indefinite oxygen supply isn’t really feasible. Enter the Silk Leaf: a manmade “plant” that can actually create endless oxygen using light and water.

Julian Melchiorri wanted to create a way to produce oxygen in space that could handle the harsh environment of interstellar travel. What he created is an artificial leaf that has the chloroplast from the plants we know and love actually suspended inside. Melchiorri used a silk fiber to suspend the chloroplast in place so that it can still act like a plant but with a sort of super-structure to make it extra durable.

Related: NASA to Launch New Ultra-Light Inflatable Habitats for the International Space Station

“I extracted chloroplasts from plant cells and placed them inside this silk protein. As an outcome I have the first photosynthetic material that is living and breathing as a leaf does, “Melchiorri told Dezeen. He also says that he wanted to build off of nature’s own system to take advantage of a proven method and the leaves won’t just be handy for exploring the far reaches of the galaxy. Back here on Earth, they can be used as biological air filters or oxygen producers.

Images via Dezeen/Julian Melchiorri

Introducing the All-Wheel Drive Model S 70D | Tesla Motors

Today (April 8th 2015) we are introducing the Model S 70D, an all-wheel drive electric car with a 0-60 time of 5.2 seconds and a 240 mile range at 65 mph.

Even at a starting price of $75k, the Model S 70D offers a broad and compelling set of features. Moreover, when one factors in the cost advantages over an internal combustion engine vehicle, including fuel savings and incentives, the actual cost of owning Model S 70D comes to about $55k over five years (the average length of new car ownership).

In addition to having independently operational front and rear motors, the 70D includes Supercharging to enable free long-distance travel, Autopilot hardware, navigation, blind spot detection and many other features. As with every Model S, the 70D will receive free over-the-air updates that add functionality and improve the driving experience for years to come.

Starting today, you can also order any Model S in three new colors: Ocean Blue, Obsidian Black, and Warm Silver.

How do you plant 1 billion trees a year? With drones, of course

Instead of doing surveillance or carrying out military missions, the drones from BioCarbon Engineering are taking on a decidedly more progressive task: planting trees and reversing deforestation.Drones, or unmanned aerial vehicles (UAVs), have taken off in popularity recently, with hobbyists and professionals alike using these small remotely-guided devices for everything from delivering packages to surveying wildlife populations, but one startup has a very ambitious plan for their drones, and one that could have a huge positive impact on global deforestation.

“We are going to counter industrial scale deforestation using industrial scale reforestation. Destruction of global forests from lumber, mining, agriculture, and urban expansion destroys 26 billion trees each year. We believe that this industrial scale deforestation is best combated using the latest automation technologies.” – BioCarbon Engineering

© BioCarbon Engineering

© BioCarbon Engineering

BioCarbon Engineering, based in the UK, has developed a system of planting trees with drones, at just a fraction of the cost (15%) of traditional reforestation methods, and at a speed that manual planting can’t match – up to 10s of thousands of trees planted per day – and aims to plant 1 billion trees per year using this technology.

This approach, using an industrial-scale reforestation method, isn’t quite ready for prime-time, but its prototype, which won £20k in funding from the Skoll Centre for Social Entrepreneurship last year, is expected to be built into a fully functioning platform by the end of the year.

The BioCarbon Engineering drone tree planting system doesn’t just send out quadcopters full of tree seeds to disperse them over the land, but instead first uses detailed terrain data to build high resolution 3D maps of the areas to be reforested. The planting drones then fly out and perform “precision planting activities” in those areas, by firing a pregerminated seed pod into the soil with pressurized air, with the pod being encapsulated in a nutrient-rich hydrogel for “high up-take rates.” After planting, the drones will also be used to audit and monitor the reforested sections to assess the recovery of the areas.

“There are a variety of tree-planting techniques, including planting by hand and delivering dry seeds by air. However, hand-planting is slow and expensive, and spreading dry seeds results in low uptake rates.

Our solution balances these two methods. First, by planting germinated seeds using precision agriculture techniques, we increase uptake rates. Second, our scalable, automated technology significantly reduces the manpower requirements and costs. Finally, our mapping UAVs will also provide invaluable intelligence on planting patterns, landscape design and appropriate timing.” – BioCarbon Engineering

As great as the BioCarbon drone tree-planting program looks at first glance, there are a number of questions that come to mind for me, including the long-term viability of UAV-planted seeds, based on the limited usefulness of other aerial seed broadcasting systems that have already been trialled. Hand planting of tree seedlings by trained foresters has a fairly high rate of success, as it allows for humans to make the call as to exactly where and how deep to plant the baby trees, whereas shooting tree seeds into the soil seems like it would be prone to high failure rates. And if this system will be used to plant monoculture forests, as is often the case when replanting clear cuts, then is it any better for the ecosystem in the long run than traditional reforestation efforts?

For now, don’t wait for the drone tree planters to do all the work, because it may be years before we see this system adopted. And even if you can’t plant thousands of seedlings per day, you certainly can plant and nurture at least a few appropriate trees in your yard or neighborhood each year, and with much more precision and care than any flying robot can.

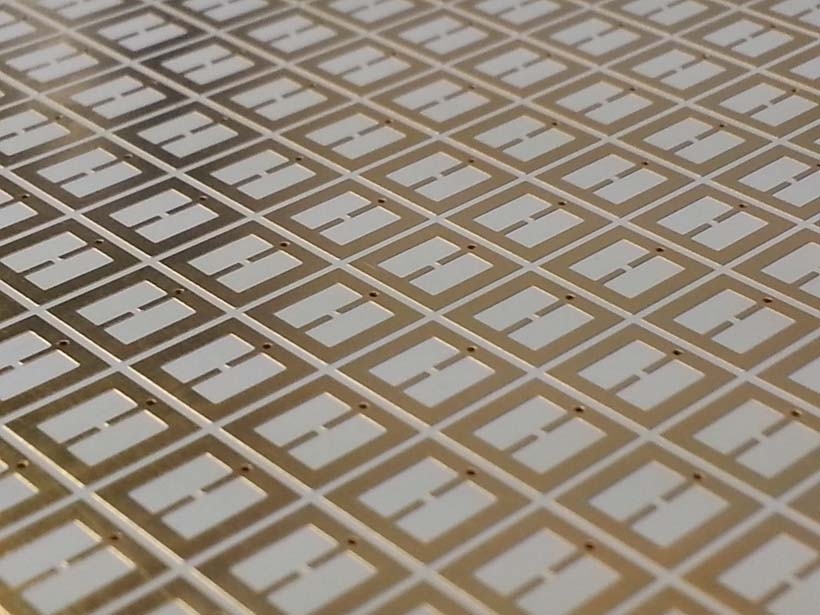

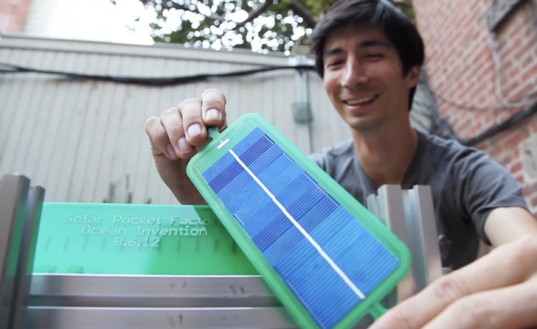

DIY Solar Pocket Factory Machine Can Print a Solar Panel Every 15 Seconds!

Inventors Shawn Frayne and Alex Hornstein are looking to revolutionize the business of small-scale solar panels with The Solar Pocket Factory, a backyard photovoltaic panel printing system. Successfully funded by a Kickstarter campaign, the two have placed themselves at the forefront of the micro solar movement, which aims to cheaply and quickly produce small PV panels.

Enthusiastic about all things solar, inventors Shawn Frayne and Alex Hornstein have built everything from lights to USB distribution grids. Through the process of designing and manufacturing their products, they found that the micro solar panels they used to power their devices were brittle, expensive, and poorly made. Taking matters into their own hands, they traveled the world and spent months researching current models. They found that half of the cost of conventional panels lay in their assembly, as many parts of the body are pieced and soldered by hand. They also observed that 15% of panels contained flaws from imperfect soldering, and in many cases, the materials used were cut-rate and disintegrated over the period of a few years.

They figured that if they could automate the production, they could eliminate 25% of the price tag and reducing the number of defects. By using higher quality materials, they could also create panels that are more efficient, gather more light, and last longer. The result of their labor is The Solar Pocket Factory, a small automated machine that can churn out panels on a smaller scale than a sprawling factory. The device resembles a desktop 3D printer, and the team hopes to have a full working model completed by April. When finished, the Solar Pocket Factory will be able to churn out a panel every 15 seconds – that means that just one machine could potentially power 1 million devices each year! Viva la revolucion!